Galena Processing Plant, Gravity Separator of Galena, galena ore beneficiation solution

The main method for the beneficiation of galena is flotation. Due to the natural floatability of galena, high-quality galena concentrate can be produced through flotation with satisfactory beneficiation indicators.

However, the investment in flotation equipment is huge, the production cost is high, and it also has obvious pollution to the environment. Therefore, more and more people are considering adopting a new type of galena beneficiation process to reduce the cost of beneficiation and equipment investment, and at the same time will not cause pollution to the environment. It’s a galena gravity separation process.

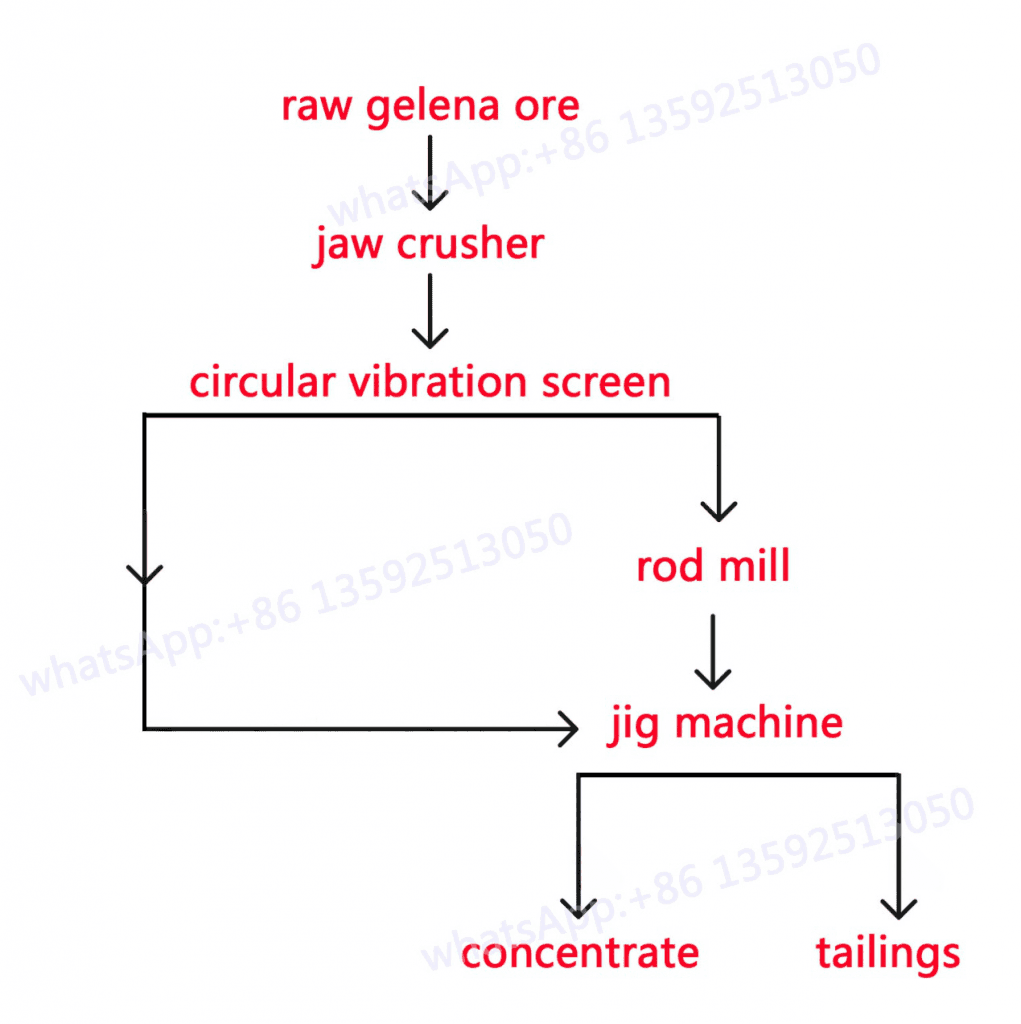

The following is the galena gravity separation process.

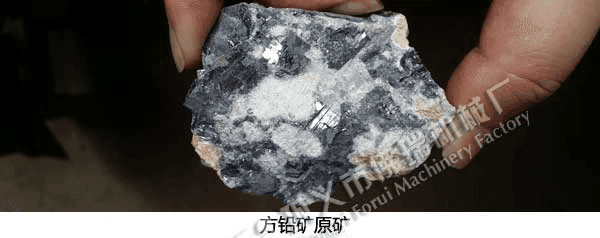

The galena in this photo is coarse-grained galena. There is a clear boundary between galena and gangue, and lead minerals and gangue monomers can be dissociated by crushing. Because the specific gravity of galena is relatively large, up to 7.4-7.6, while the specific gravity of gangue usually does not exceed 3.0, gravity separation can get a good beneficiation effect.

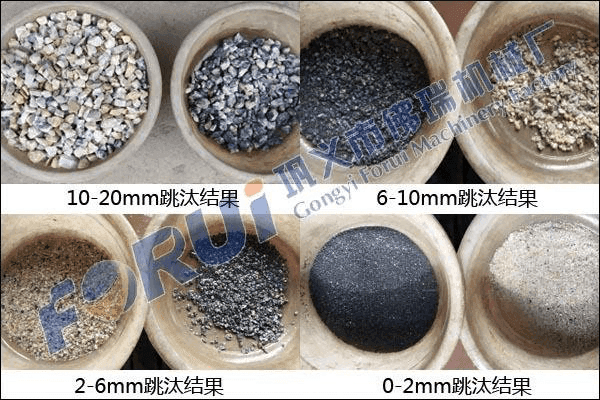

The picture below shows the concentrate and tailings separated from galena by gravity separation with a jig machine.

Let’s see how galena ore is processed by gravity separation with our lab machines :

Galena beneficiation solution:

The raw ore is sent to the jaw crusher for coarse crushing. Because galena ores are fragile, some lead minerals have been dissociated from the rock after coarse crushing. This part of the material is screened out through a circular vibrating screen and directly enters the jig machine to avoid over-crushing caused by secondary crushing. The other part of the material enters the rod mill for the secondary crushing to break the conjoined body of lead minerals and gangue, and completely release the lead minerals from the ore.

(Although the rod mill is a kind of grinding equipment, it is widely used in the field of fine crushing of fragile materials. Its application can effectively reduce the phenomenon of galena over-crushing. At the same time, the grinding particle size is uniform and the production efficiency is high. Suitable for fine crushing of galena.)

The secondary-crushing material directly enters the jig machine for concentration to obtain the final concentrate.

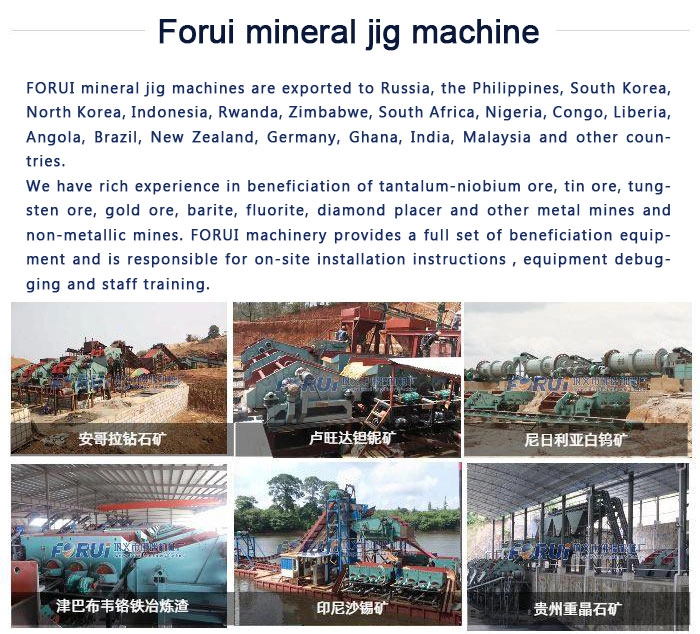

The gravity separation separator commonly used for beneficiation of galena is a jig machine. For the coarse-grained galena, we can use the AM30 jig machine, and the selected size of this jig machine can reach 30mm. For that fine-grained galena, we can use the 2LTC-6109/8T jig machine. This jig machine is aimed at 0-8mm fine minerals. It not only has a large processing capacity, but also has four different jigs chamber. The system can sort minerals of different sizes at the same time.

Some galena ore grades are very low, and the cost of direct flotation is too high. For this type of galena, it is necessary to raise the grade by gravity separation before flotation. This will greatly improve the efficiency of beneficiation.

Responses