Mining of Alluvial Gold Ore Deposits

In the last article, we introduced ‘Sampling and Analysis of Alluvial Gold Ore Deposits‘.

The topic I want to share with you today is ‘Mining of Alluvial Gold Ore Deposits’. In this article, I will introduce some common mining methods for ALLUVIAL GOLD ORE.

What kind of mining equipment determines what kind of mining method, also determines the cost of mining. A friend always asks me if he is going somewhere to do a gold ore dressing business, intends to mine with some equipments, plans to invest a certain amount of money, etc. I said, ‘Have you been on the spot?’ He said not yet. In this case, I knew that he probably had no experience in such a business as ore dressing. It is generally suggested that he find a good master to go to the mine field investigation. This master must have many years of practical gold mining experience. Years of experience means that he has practical experience in all types of ore body mining. He can give you advice on how to design a mining plan based on the thickness of the ore body, the granularity of sand, the factors above ground and groundwater, etc. So as to avoid detours.

At present, there are two main mining methods: open pit mining and underground mining. It can be seen that different mining methods also determine the different equipment used. At the same time, the actual condition of ore body determines the size and number of different equipment.

1.Overview of Alluvial Gold Deposit Mining

Here I mainly introduce the method of opencast mining. Open-pit mining of alluvial gold is divided into three categories according to the different mining machinery used:

(1) Gold Dredger mining: it is a combination mining, walking and washing and selecting facilities in one, floating on the water. On the ship, the mining, sorting and transportation of the ore tailings constitute a complete technological process.

(2) Open-pit mining of construction machinery: it refers to excavating and loading ore and rock with construction machinery such as mechanical shovel, bulldozer, scraper and loader. The alluvial gold deposit is mined by using belt conveyors, truck scrapers and loaders to transport ore rocks mechanically. Suitable for use in dry areas. The bulldozer mining method, front-end loader mining method, scraper mining method and mechanical shovel mining method introduced below all belong to the open-pit mining method of construction machinery.

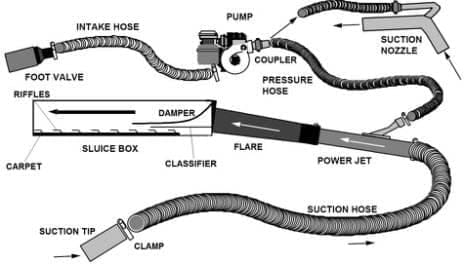

(3) Hydraulic machinery mining: The main equipment of this method includes water gun, sand pump and water pump. It is a continuous production process that USES the same water flow to successively complete the work of blanking, transportation, washing and tailings discharge.

2.Gold Dredger and its Production Techniques

Gold Dredger is a kind of equipment which gathers mining and dressing functions. It’s actually a gondola. It floats on rivers and lakes, or in the foundation pits it opens. The ship is equipped with multi-bucket excavators, alluvial gold beneficiation equipment and tailings discharge equipment. Both mining and dressing processes can be completed simultaneously.

The ore extracted from the chain bucket under water is sent to the washing drum sieve through the loading funnel. The underscreen products and water are distributed to the dressing equipment through the slurry distributor. The sieve of the drum sieve is gravel and mud. The gravel and mud masses are transported by a belt conveyer to the gob at the stern of the ship through the gravel chute to form a gravel pile. Tailings are discharged to the rear of the Gold Dredger through the tailings trough or pipe to form a tailings pile.

2.1 Gold Dredger Development Method

The first step in mining alluvial gold deposits is to exploit them. To exploit is to place Gold Dredger on a certain level. It makes it close to the ore body in the floating state and creates conditions for further mining the ore body. The development methods are as follows:

(1) Excavation method: Dig a pit for placing Gold Dredger along the boundary of the ore body or near the ore body. The size of the pit is determined by the specifications of the gold dredger, and the depth by the depth of the water required for the gold dredger to float. This method cannot be used when the underwater burial depth of the deposit is less than the minimum underwater burial depth of the alluvial gold ore limited by the draft condition of the gold dredger.

(2) Dam-building development method: Permanent or temporary retaining DAMS should be built in the river valley to raise the water level of the mining pool so that Gold Dredger can enter the mining area.

(3) Cofferdam development method: When the water level needed to be raised by Gold Dredger is not large, it is not necessary to build a higher permanent dam, but to build a lower earth dam. This method is called cofferdam development.

(4) Independent horizontal development method: essentially, the gold dredger is built in the foundation pit, but it only mines the deep part of the alluvial gold ore. Alluvial gold ore upper need bulldozer, scraper and other excavating equipment mining. Because this method divides the placer layer into several stages, it is also called stage development method.

2.2 Gold Dredger Mining Method

Exploitation can be carried out after the completion of the exploitation operation. According to the number of working faces in the mining pool and the movement direction of Gold Dredger relative to the axis of the valley, the mining methods can be divided into:

(1) Single working face mining method: in the mining process, the Gold Dredger always USES a working face to push forward. According to the moving direction of Gold Dredger, this method can be divided into longitudinal mining method and lateral mining method.

(2) Adjacent working face mining method: Gold Dredger take turns mining in several adjacent working faces that are connected with each other.

(3) Joint mining method: the combined application of the above two mining methods.

3.Open-pit Mining of Construction Machinery

3.1 Bulldozer Mining for Alluvial Gold

The bulldozer is a kind of self-propelled earth-moving machinery, which can complete the whole process of digging, transporting and loading. Bulldozer includes crawler type and wheel type. Crawler bulldozer is divided into high specific pressure, medium specific pressure, low specific pressure 3 kinds. High ratio bulldozer, suitable for rock stripping in stone work. Medium specific bulldozer, suitable for general earth-moving operations. Low ratio bulldozer, suitable for wetland and marsh area operation.

Bulldozers move topsoil directly from a mining site to a dump. The dump is located on the side of the quarry. In placer mining, bulldozers are generally used in conjunction with other equipment:

(1) Bulldozer – belt conveyor mining: Firstly, the ore body is divided into several mining areas, and a loading funnel is set in the center of the mining area. A bulldozer is used to push ore from the mining area to the funnel. The ore is then transported to the washing equipment by the belt conveyor.

(2) Bulldozer – mechanical shovel mining: bulldozer as the main mining equipment, mechanical shovel loading role. The purpose is to improve the mining efficiency when mining the thinner seam.

(3) Bulldozer one half shovel mining: this method has not been used in China, other countries use more.

(4) Bulldozer – front-end loader mining.

(5) Bulldozer – water gun mining: first use bulldozer to push the ore to the appropriate place. The ore is then rinsed with a water gun. The ore is then transported to the concentrator by means of hydraulic transport.

3.2 Front-end Loader Mining Method

The front-end loader is a diesel engine driven hydraulically operated device. In addition to shovel loading, but also transport, unloading. It has two types: caterpillar type and rubber wheel type. The crawler type can only be used for loading and can operate on extremely soft ground and uneven stope. The wheel type can be installed and transported by itself, which is flexible, and is an ideal mining equipment for alluvial gold mining.

In production practice, the front-end loader is used for self-loading and self-transporting only in the case of short haul. When the haul distance is large, it is generally transported by car or belt conveyor.

3.3 Scraper Mining Method

The scraper is a kind of circulating earth-moving machine. The scraper can be integrated to complete shovel, load, transport, and rock and soil discharge four operations. The scraper is mainly used for medium – distance large-scale ore mining operations. There are two basic types of scraper for mining ore: crawler scraper and wheel scraper. The crawler tractor is composed of a tractor, a bucket and a bucket control mechanism. It is commonly used in small scale stripping operations with short haul and soft ground. The wheel type tractor scraper is composed of a cartridge truck, a bucket and a bucket control mechanism. The wheel type tractor scraper is suitable for large scale stripping operation with long haul distance and hard ground.

The mining method of the scraper: the local surface terrain conditions are good, with good roads and short haul distance, the scraper can be used directly to the concentrator to receive the silo for ore. When the ore layer and the topsoil are not thick enough, the mining method of alternately mining and stripping the topsoil can be used.

3.4 Mechanical Shovel Mining Method

Mechanical shovel is a kind of machinery with a shovel, there are single bucket shovel and multi bucket shovel two categories. The connection mode of single bucket shovel and fuselage is divided into two kinds: steel connection and flexible connection of bucket. The former is called mechanical shovel or excavator, there are shovel and backhoe points. The latter mainly has the rope bucket shovel and grasps the shovel. Multi bucket shovel is divided into wheel bucket shovel and chain bucket shovel.

In the actual production of the use of a single bucket shovel – car mining method and a single bucket shovel – belt conveyor mining method. The advantage of single shovel – car mining method is that the vehicle transportation of soil and rock transport distance is large, flexible. The single-bucket shovel-belt conveyor mining method adopts belt conveyor transportation, and the receiving funnel and feeding device must be set up to ensure the uniform supply of ore to the belt conveyor. The ore extracted by the bucket is discharged directly into the receiving hopper. Then the ore is supplied evenly to the belt conveyor by the feeder. The belt conveyor takes the ore to the concentrator.

4.Hydraulic Mechanized Mining Method

Hydraulic mining is a method to complete the process of gold ore mining by high-pressure water injected by high-pressure water gun. The water is pumped into the nozzle. The high-pressure water column fired by the high-pressure water gun impinges on the working face, which causes the ore sand to collapse and break to form the slurry and flows into the slurry pond along the ore gully. Then it is pumped by sand pump to the gold dressing plant.

The production process of hydraulic mining is as follows:

(1) Topsoil stripping: remove the thick topsoil with machinery (tractor, bulldozer, etc.), and remove the thin topsoil with water gun impact.

(2) Ore mining: use water gun high-pressure water column to impact the working face to make ore collapse and fragmentation.

(3) Hydraulic transport: that is, the mined ore flows into the slurry pond and is then pumped to the gold concentrator by the sand pump.

The hydraulic mining method is suitable for the generally cemented and not too hard orebody, and requires the orebody to be buried shallower and the floor level. This method has the advantages of less capital construction investment, short construction period, high recovery rate of mining, simple equipment and easy maintenance. The shortcoming is high power consumption, sand pump conveying sand technology still needs to be improved.

If you have any comments or suggestions, please feel free to leave a comment below or contact me directly.

The next post I will share with you is ‘Alluvial Gold Beneficiation Method: It’s Not As Difficult As You Think‘.

Gongyi Forui machinery factory, founded in 1986. We are one of the leading suppliers of beneficiation equipments in Asia. Don’t hesitate to Contact Us, if you have any question of beneficiation. And welcome to visit our company. Gongyi Forui Machinery Factory dedicated to serve you!

Responses