Alluvial Gold Beneficiation Technology and Beneficiation Equipment

What is Placer Gold, Type of Alluvial Gold Mine

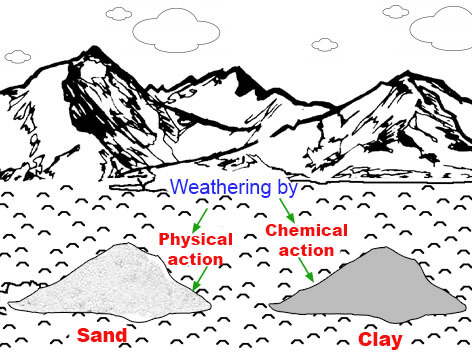

Placer gold deposits are gold-bearing mixed sand deposits formed by long-term weathering of vein gold deposits. Due to long-term river water transportation, three natural types of residual placer gold deposits, slope deposit placer gold deposits, and alluvial placer gold deposits have naturally formed. Among them, alluvial placer gold mines have the most industrial mining value and can be subdivided into bank placer gold mines, river valley placer gold mines, river beach placer gold mines, and river bed placer gold mines.

Placer Gold Extraction Process

According to the nature of placer gold ore, the beneficiation process of placer gold ore can be divided into placer gold ore washing, screening, gravity beneficiation roughing, and beneficiation.

Ore Washing and Screening Equipment

Placer gold mines can be divided into easy-to-wash (mud content <10%), medium washable (mud content 10%-15%), and hard-to-wash (mud content 15%-30%) according to different mud content. ) And the hardest to wash (mud content>30%). It also contains impurities such as boulders (+100-200mm), pebbles (-100+25mm), gravel (-25+0.2mm) and silt (-0.1~0.2mm). Commonly used ore washing and screening equipment include: cylinder washing machine, trough washing machine, drum screen, vibrating screen and so on.

Placer Gold Gravity Beneficiation Equipment

After washing and sieving the placer gold ore, the gold can be recovered with gravity beneficiation equipment such as a sluice box, jig, spiral concentrator, and shaker.

Use the Sluice Box to Beneficiate the Placer Gold

Sluice box is the simplest gravity beneficiation equipment for placer gold mines. It has four advantages:

- Large processing capacity.

- The enrichment ratio is high.

- Wide range of beneficiation particle size.

- The beneficiation cost is low.

The beneficiation of placer gold ore by the sluice box is often related to the following factors:

- The width of a 1-meter long sluice box or a processing capacity of 1 square meter.

- The inclination of the sluice box.

- The concentration of the slurry.

- The flow rate of the slurry.

- Cover materials and shapes.

- Grain size composition of placer gold ore.

- The content of heavy sand.

- A number of rinses.

When the sluice box is used for beneficiation of placer gold ore, the length of the sluice box is of little significance, because the specific gravity difference between gold and gangue is greater than 16, and most of the gold will be recovered at the head of the sluice box. When extracting coarse-grained gold, the length of the coarse-grained filling sluice box is 15-20 meters, sometimes as long as 100 meters. When extracting fine-grained gold, the length of the fine-grained filling sluice box is about 5-6 meters.

Jigging Machine for Beneficiation of Placer Gold Ore

The jigging machine has the characteristics of large processing capacity and high recovery rate, and the recovery rate of gold in fine-grained placer gold ore can reach 90-94%. The jig machine’s gold ore index is often closely related to the type, composition, shape, size, and mud content of the ore.

Shaker to Select Placer Gold Ore

The processing capacity of the alluvial gold beneficiated by the shaking table is small, but the enrichment ratio of the concentrate produced by it is high. It is suitable for the beneficiation process, for example, it can be used for the beneficiation of coarse concentrates from jigs, sluice boxes, and spiral concentrators. The recovery rate of the beneficiation process of the shaker can reach 98-99%. Shakers can be divided into two types: coarse sand shakers and mineral mud shakers

Gold Mining Ship Selects Placer Gold Mine

The modern gold dredger is a complex mining system, which includes functions such as mining, ore dressing, and tailings transportation. It is one of the most economical and effective methods for beneficiating gold ore. The gold dredger is mainly used for mining alluvial placer gold mines and seaside placer gold mines. It is usually divided into two types:

- A land-based gold dredger that mines mainland placer gold mines.

- Marine gold dredger for mining seaside placer gold mines.

The beneficiation on the gold mining ship is often related to the beneficiation equipment, the beneficiation process, and the rough concentrate beneficiation method. The simplest process for extracting placer gold is:

- Only use the sluice box process.

- Only the process of the jigging machine is used.

A complex process may be a combined process that includes multiple pieces of equipment such as shakers, sluice boxes, jigs, and amalgam barrels at the same time.

Beneficiation of Placer Gold Mine

The coarse concentrate of placer gold is often mixed with some heavy minerals with a relatively large proportion, such as cassiterite, scheelite, wolframite, ilmenite, chromite, magnetite, zircon, and corundum, and other minerals. The beneficiation of the selected process flow is related to the type of heavy sand, the nature of heavy sand, and the gold content. A reasonable beneficiation process can not only process the coarse concentrate of gravity beneficiation but also process various selected products and separate useful minerals.

You may also be interested in the following articles:

- Very Simple And Efficient Placer Gold Beneficiation Program

- Simple, High-YIELD Gravity Gold Concentration Program

Gongyi Forui Machinery Factory, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. Welcome to visit our company. Gongyi Forui Machinery Factory dedicated to serving you! Don’t hesitate to Contact Us, if you have any questions about beneficiation:

- Whatsapp: +8618026978087

- Email: asa.guo@foruimining.com

Responses