Diamond Beneficiation Technology and Diamond Beneficiation Equipment

Diamond Beneficiation Process

Diamond refers to diamonds that have been polished. Diamond is a natural mineral. It is the rough diamond. Simply put, a diamond is a simple crystal composed of carbon that is formed under high pressure and high-temperature conditions inside the earth’s crust. As a mineral resource, the market price of a diamond is indeed high, but the content of diamond in the ore is indeed very low. To extract diamond from ore, it must go through a process of beneficiation and purification.

The beneficiation process of primary diamond ore mainly depends on the nature of the original ore, the scale of the beneficiation plant, and other factors. To design a reasonable process, it is necessary to protect the diamond crystal from being damaged or to minimize the degree of damage as much as possible. This requires us to determine a reasonable crushing process, determine a suitable ore size range, and comprehensively recover fine diamonds and useful associated minerals as much as possible. Only in this way can we ensure a higher recovery rate and profit.

Diamond Beneficiation Method – Grease Beneficiation Method

The earliest beneficiation method for a diamond is the grease beneficiation method, which is one of the main beneficiation methods for diamonds. The theoretical basis of the diamond grease beneficiation method is that in the separation system, diamonds are oleophilic and hydrophobic (diamonds are adhered to the grease), while other gangue minerals are hydrophilic and oleophobic (flowing along the direction of the flushing water flow). The physical characteristics of the tailings bucket), so as to realize the sorting process.

Prior to this, the rough concentrate of the diamond concentrator was directly selected by hand. This method is not only a lot of work but also difficult to guarantee quality. When the grease beneficiation method is adopted, the manual separation workload is reduced to l/800 before, and the work efficiency is increased hundreds of times. Therefore, people in the industry have reason to believe that the grease beneficiation method is the second milestone in the history of diamond beneficiation.

Diamond Beneficiation Equipment

Diamond Roughing Equipment

The diamond beneficiation jig machines that can be processed without grading are also called trapezoidal jigs (side-moving diaphragm jigs), which are gravity beneficiation equipment. Trapezoidal jigs use water as the beneficiation medium and perform beneficiation according to the difference in the proportions of minerals and gangue. It has four independent beneficiation troughs, each trough can be adjusted independently, the jigging surface is trapezoidal, it has a high recovery rate and processing capacity. It is widely used in the processing of the following minerals: hematite, limonite, ore, manganese ore, tungsten ore, tin ore, tantalum niobium ore, mercury ore, fluorite ore, barite ore, lapis lazolite, and other metallic and non-metallic minerals. Trapezoidal jigs can also be used to process metal smelting slag and to recover alloy particles and recyclable materials in metal smelting slag.

The trapezoid jig machine consists of eight jigging chambers, divided into two rows, each with four chambers. It widens gradually from the feeding end to the discharging end, and if you look down on it, the whole machine is trapezoidal. The machine has a large processing capacity and strong adaptability. It is suitable for the beneficiation of medium-grained and fine-grained ores, and the effective recovery limit is 53 microns. Trapezoidal jigs have been widely used in gravity concentrators for iron ore, manganese ore, tin ore, etc. around the world.

Diamond Separation Equipment

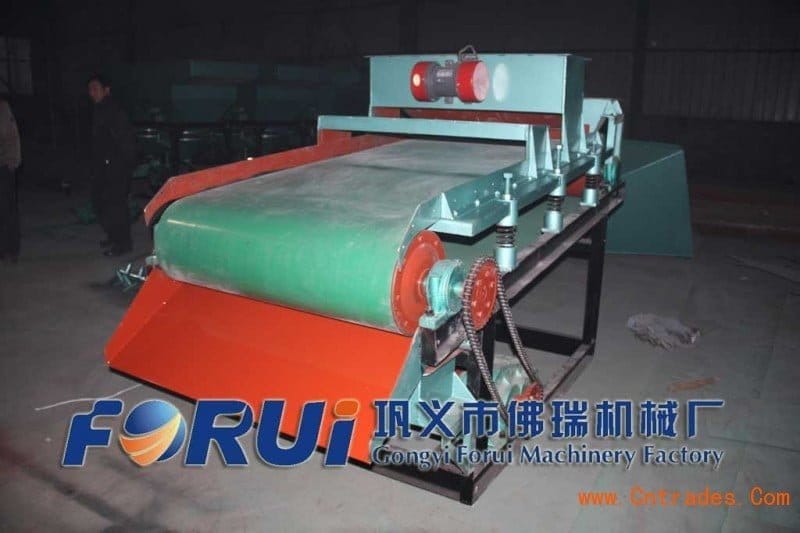

The beneficiation working surface of the vibrating belt type grease concentrator is a sorting belt, which is a stepless conveyor belt around the first wheel and the tail wheel. It has a certain angle with the horizontal, and the angle can be adjusted according to the feed size. The first wheel and the tail wheel are installed on the frame, and the material is fed to the sorting belt by the vibrating feeder, and there is a flushing water pipe on the belt. The oiling tank is installed at the tail wheel end of the belt so that the heated grease in the tank is continuously coated on the sorting belt along with the movement of the sorting belt. An electric scraper is installed at the first round of the sorting belt to continuously scrape off a certain thickness of grease with mineral particles. After deoiling the grease containing mineral particles, the concentrate can be obtained. After the concentrate is dried, the diamond can be obtained by hand selection. The gangue that cannot stick to the surface of the grease is washed into the tailing tank by the washing water.

After practice, the improved vibrating grease concentrator is equipped with a vibrating device under the sorting belt, which makes the sorting belt vibrate in the vertical direction, increases the number of times the mineral particles contact the surface of the grease, and helps improve the recovery rate of the beneficiation. The vibrating grease concentrator has three times the processing capacity of the non-vibrating grease concentrator.

Learn More:

Gongyi Forui Machinery Factory is a professional manufacturer of beneficiation equipment. Our factory has designed diamond beneficiation technology and equipment configuration for multiple diamond beneficiation plants and has a small test platform, which can conduct small-scale washing tests and designs for customers free of charge. Process flow, welcome to inquire, contact number: +8618026978087

Responses