Discussion on Beneficiation Technology of Tantalum-niobium Ore

Introduction to Tantalum Niobium Mine

Tantalum-niobium ore refers to the general name of minerals containing tantalum and niobium, and there are more than one hundred species. The main types that can be used for ore mining are tantalite, columbite, and pyrochlore. Tantalite contains more tantalum called tantalite and contains more niobium called columbite. The following picture shows the original tantalum-niobium ore mining site in a country in Africa:

The following is the worksite of the complete set of tantalum-niobium ore beneficiation production line provided by Forui Machinery for the African tantalum-niobium ore beneficiation plant:

Tantalum-niobium Ore Beneficiation Technology

The beneficiation process of tantalum-niobium ore needs to be determined according to the characteristics and structure of the original ore. Under normal circumstances, we divide tantalum-niobium ore into two types according to the difficulty of beneficiation. One is the refractory tantalum-niobium ore with complex structure and complex composition, and the other is the tantalum-niobium ore with simple structure and single composition. The tantalum-niobium ore in China and the tantalum-niobium ore in Africa are in sharp contrast, becoming the representative of these two tantalum-niobium ores.

China’s Tantalum-niobium Ore Beneficiation Technology

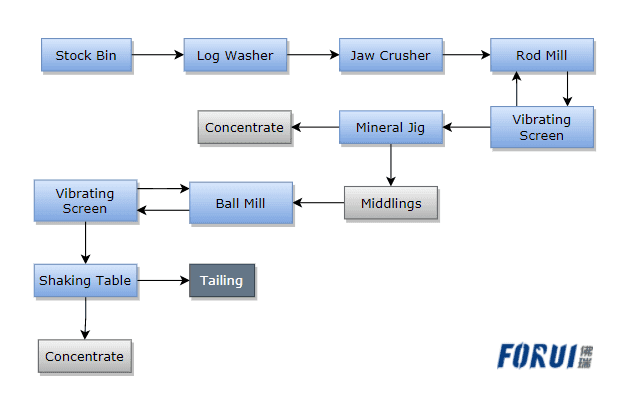

The grade of tantalum-niobium ore in China is generally very low, the minerals are relatively brittle, and the density is relatively high. Generally, the process of segmented grinding and segmented beneficiation is used. The tantalum-niobium mine in Yichun, Jiangxi, China adopted the process of staged grinding and staged gravity beneficiation, and finally obtained a 14.94% tantalum-niobium concentrate with a recovery rate of 75%.

The No. 69 ore body in the Dajishan Tungsten Mine in Jiangxi, China is a large granite ore body containing tantalum, niobium, and tungsten. Its main minerals include wolframite, scheelite, tantalite, and fine stone. Because of the extremely fine particle size of the useful minerals embedded in this mineral, the recovery rate of the conventional gravity beneficiation method is very low, so it needs to be recovered by flotation technology. The Guangzhou Research Institute of Nonferrous Metals uses a combined gravity separation-flotation process to recover tantalum and niobium. The final concentrate obtained contains 10.84% tungsten trioxide and 51.8% tantalum pentoxide. The recovery rate of the original ore is 69.92% (the recovery rate of Ta2O5 is 69.071%), the recovery rate of the beneficiation process is 94.11%. The yield of tin concentrate is 0.0581%, containing Sn 60.25%, the recovery rate of the original ore is 58.49%, and the recovery rate of the beneficiation process is 89.84%.

For the complex and difficult-to-select tantalum-niobium ore, we generally use a combination of gravity beneficiation, flotation, magnetic separation, and a combination of multiple methods. If you want to determine the beneficiation process of tantalum-niobium ore, you must understand the properties and structural characteristics of the tantalum-niobium ore. Although the reserves of tantalum-niobium ore in China are poor, the beneficiation technology of tantalum-niobium ore is not backward. Regarding the beneficiation of tantalum-niobium ore, we have a lot of practical experience and unique technology. Welcome to inquire or go to the factory for a beneficiation test. Contact number: +8618026978087.

The figure below is a schematic diagram of the beneficiation process of a fine-grained embedded tantalum-niobium ore in China:

Beneficiation Technology of African Tantalum Niobium Ore

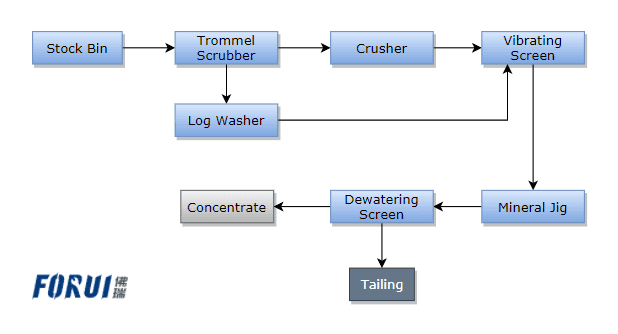

The structure of African tantalum niobium ore is simple, the composition is relatively single, and the beneficiation method is very simple. Its beneficiation process is generally divided into two stages: roughing and beneficiation. The coarse beneficiation stage uses ore washing and gravity beneficiation to obtain coarse concentrate, and the beneficiation stage uses strong magnetic separation to obtain the final concentrate.

Forui Machinery has successively designed the beneficiation process and equipment configuration schemes for the tantalum-niobium ore beneficiation plants in Nigeria, Rwanda, Angola, and other African countries. It has rich experience and unique insights on the beneficiation of African tantalum-niobium ore and can provide the owner with feasibility Suggest. Our factory has set up a small-scale test platform, which can also conduct beneficiation tests on samples brought by customers and can decide whether to purchase our equipment according to the beneficiation effect. Please feel free to contact us: +8618026978087.

The tantalum-niobium-tin ore beneficiation test carried out by our factory for Nigerian customers uses ore washing, screening, jigging, and other processes. The final concentrate contains 46% tantalum-niobium, 5-6% tin, and a recovery rate of 86. %.

The tantalum-niobium-tin ore beneficiation process we performed for our Rwandan customers also uses this process.

The obtained concentrate contains 51% tantalum-niobium, 7.1% tin, and a recovery rate of 79%. At Forui Machinery, the use of simple craftsmanship and minimal investment can create huge economic benefits for customers, which has won unanimous recognition and praise from customers.

If you are also interested in the beneficiation process and equipment of African tantalum niobium ore, please feel free to contact us, we will provide you with the most perfect service and the best quality products. The following figure shows the schematic diagram of the beneficiation process of Nigeria and Rwanda coarse-grained tantalum-niobium ore deposits:

Tantalum-niobium Ore Beneficiation Equipment

The beneficiation equipment and beneficiation technology of tantalum-niobium ore are closely related. China’s complex tantalum-niobium ore beneficiation process requires a lot of equipment, such as crushers, ball mills, linear vibrating screens, high-frequency vibrating fine screens, spiral chutes, shakers, jigs, flotation machines, etc.

The beneficiation equipment of African tantalum-niobium ore only needs to use an ore washing machine, vibrating screen, jig machine, magnetic separator, and other equipment to meet the final requirements. Different types of tantalum-niobium ore beneficiation equipment in different regions require different types of tantalum-niobium ore beneficiation equipment.

If you want to buy a set of satisfactory tantalum-niobium ore beneficiation equipment, you must find a professional beneficiation equipment manufacturer. In addition, the manufacturer must have rich experience in the beneficiation of tantalum-niobium ore, and it is best to conduct a beneficiation test on-site to ensure that it is foolproof.

Current Status of Tantalum-niobium Ore Beneficiation

China’s tantalum and niobium ore resources are scarce, and most of them are complex and difficult to select fine-grained embedded tantalum and niobium ore. General small and medium-sized investors are not willing to invest in such mineral resources. Although the African economy is not well developed, the tantalum-niobium ore resources are rich, the ore composition is single, the structure is simple, and it is an easy-to-dress mineral. Therefore, many Chinese investors went abroad to invest in such tantalum and niobium mines and achieved great success.

In fact, investing in tantalum-niobium ore in Africa is indeed a lucrative project, because their tantalum-niobium ore reserves are rich and easy to choose from. Investors do not need to spend too much money to invest in mineral processing equipment, they can use the most conventional gravity separation equipment and magnetic separation equipment to meet the requirements. Therefore, in recent years, Chinese businessmen have invested in mineral resources throughout Africa and Southeast Asia, especially such rare resources, such as tantalum-niobium ore, diamond ore, tin ore, tungsten ore, etc. Most investors have achieved complete success.

Gongyi Forui Machinery Factory is a professional manufacturer of beneficiation equipment. Our factory has provided dozens of tantalum-niobium ore beneficiation plants with complete beneficiation solutions and tantalum-niobium ore beneficiation equipment, and provided them with detailed technical consultation and perfect After-sales service, we have obtained rich practical experience and praise from customers. Our factory has set up a small-scale test platform, which can carry out beneficiation tests for customers free of charge. Welcome to inquire and contact us at +8618026978087.

Responses