HOW TO EXTRACT TIN ORE FROM CASSITERITE, WHAT IS THE TIN ORE BENEFICIATION METHOD?

OVERVIEW

The washability of the ore is the basis for determining the beneficiation process. At the same time, the requirements of mining and smelting methods, as well as existing resources and production conditions, must also be considered. For the beneficiation of tin ore, it is necessary to understand the common characteristics of various tin ore deposits, and also to understand the characteristics of tin ore that are different from other metal ores.

Compared with general non-ferrous metal ore, tin ore has the following characteristics in terms of washability, resources, and production:

① The unity of tin minerals and the diversity of useful associated minerals.

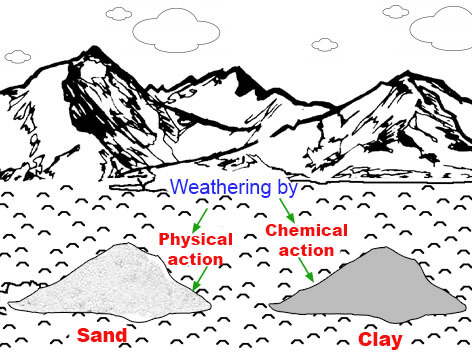

② Cassiterite has stability during natural weathering and is fragile during crushing and grinding.

③The raw ore grade and concentrate grade of cassiterite are required to be high.

④The mining area of cassiterite is relatively concentrated, but its mining and production are relatively scattered.

TIN ORE BENEFICIATION METHOD

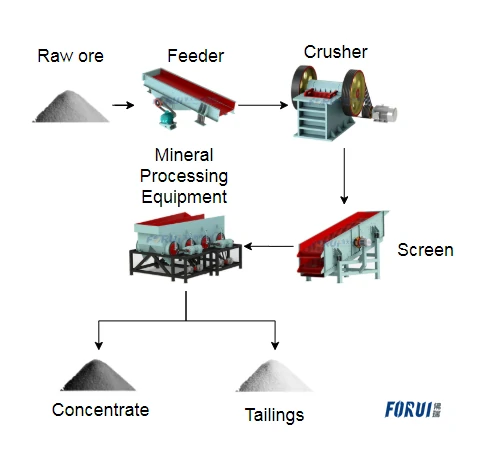

The above characteristics determine that the tin ore beneficiation method is mainly gravity beneficiation. Under normal circumstances, tin ore beneficiation also uses a combination of physical beneficiation methods (gravity beneficiation, magnetic separation, flotation, electric separation, etc.) and chemical beneficiation methods (roasting, volatilization, leaching, etc.).

In actual production, multi-stage grinding and multi-stage beneficiation are often used to beneficiate cassiterite to achieve the purpose of early harvest, and at the same time strengthen its pre-selection and desliming operations. The final product is mainly tin, and it is necessary to produce high-grade concentrates that meet the requirements of smelting and to produce other tin products with lower grades to achieve the purpose of comprehensive utilization. The scale of production should be adapted to local conditions, combining large, medium, and small.

Due to the large proportion of tin ore, the method of gravity separation is often used for the purification of tin ore. At the same time, it often combines gravity beneficiation with flotation, magnetic separation, electrostatic separation, roasting, volatile leaching, and other processes. Dense-medium beneficiation is commonly used in tin ore dressing plants. Dense-medium beneficiation is mainly used for the pre-selection of ore, that is, the preliminary purification of coarse concentrate.

TIN ORE BENEFICIATION EQUIPMENT

Commonly used beneficiation equipment includes shaker, jig, spiral concentrator, centrifuge, sluice box, etc.

At present, the shaker is the main equipment of the tin ore dressing plant. It is used to process fine-grained cassiterite of 0.037-2mm. The shaker has a high enrichment ratio, which can select high-grade concentrates and separate the final tailings. At present, most of the tin concentrate sent to the smelter is the product of shaker beneficiation. Jigs are mostly used for the purification of coarse and medium-sized cassiterite. The spiral concentrator is used to recover cassiterite with a size of 0.074~1mm. For the sludge smaller than 37μm, it is mainly purified by centrifuge and sluice box.

The application of flotation in tin ore beneficiation mainly has the following three aspects:

- Used to separate various sulfide minerals associated with tin ore.

- In the process of beneficiation, various associated minerals are separated and recovered.

- Extract fine-grained cassiterite from the sludge.

Magnetic separation and electric separation are mainly used in the process of beneficiation of coarse tin ore concentrates to separate and recover those associated minerals whose density is not much different from that of cassiterite.

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in the lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us:

- Whatsapp: +8618026978087

- Email: asa.guo@foruimining.com

- Tel: +86-371-64391589

- Facebook: https://www.facebook.com/ForuiMachinery/

- Instagram: https://www.instagram.com/foruimining/

- Twitter: https://twitter.com/ForuiMachinery

- LinkedIn: https://www.linkedin.com/in/asa-guo-benefication-equipment-at-forui/