How to Recover Ferro-nickel from Stainless Steel Slag

[Scheme Overview]

Solution of Recover Ferro-nickel from Stainless Steel Slag

Solution of Recover Ferro-nickel from Stainless Steel Slag

Solution of Recover Ferro-nickel from Stainless Steel Slag

Solution of Recover Ferro-nickel from Stainless Steel Slag

This scheme is mainly designed according to the characteristics of nickel-iron slag. This scheme adopts the recycling concept of coarse selection first and then fine selection, so as to avoid the situation that large pieces of nickel-iron alloy cannot be crushed and the crusher is damaged.

The main equipment of this program includes a jaw crusher, vibrating screen, jig machine, rod mill, dewatering screen, and other equipment. Complete the recovery of the nickel-iron alloy in the nickel-iron slag.

[Technical Advantages]

The biggest advantage of this scheme is that it can recycle coarse-grained alloys in advance to avoid large pieces of nickel-iron alloys from damaging the crushing equipment. At the same time, it can maximize the profit of the factory. In general, this solution has many advantages such as small investment, low cost, high efficiency, and low failure rate.

Stainless Steel Slag Treatment Plant

The nickel-iron slag treatment program is designed by Frey Machinery based on years of experience. It has successfully applied mechanical equipment such as a large particle jigging machine, rod mill, fine particle jigging machine, and dewatering screen. It completes the task of recovering the nickel-iron alloy in the nickel-iron slag by recovering the coarse-grained alloy first and then the fine-grained alloy.

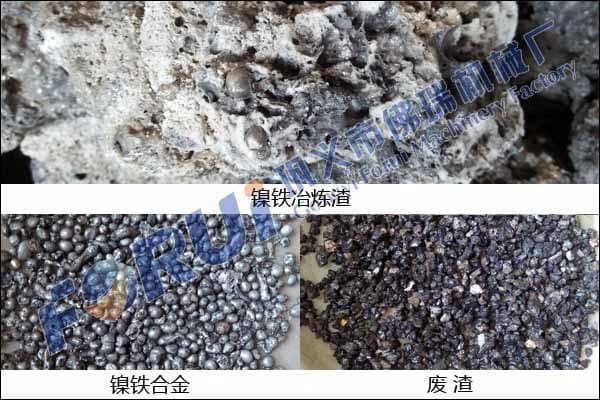

It not only maximizes profits but also avoids the problem of non-alloyable blocks damaging the crushing equipment. This program is currently the most ideal and practical program in the field of nickel-iron slag treatment. Of course, Furui Machinery can also design simplified solutions according to customer requirements to meet the needs of large, medium, and small processing plants. The picture below shows the nickel-iron alloy washed from the nickel-iron slag with a jig machine:

Features of Nickel-iron Slag Treatment Program

1. Effectively solve the problem of high nickel alloy recycling.

Nickel-iron alloys are divided into high-nickel alloys and low-nickel alloys. Low-nickel alloys can be recycled using magnetic separation technology, and high-nickel alloys have poor magnetic properties, so the magnetic separation method is not effective. This solution successfully solved the recovery problem of high nickel alloys.

2. The Profit is Maximized and the Failure Rate is Low.

In this process, coarse-grained nickel-iron alloy can be recovered first, and then fine-grained nickel-iron alloy can be recovered. It maximizes profits and reduces the probability of failure due to the blockage of the crusher due to large alloys.

3. Small Investment and Low Cost.

Using this scheme to treat nickel-iron slag has low investment, low cost, and high production efficiency. It is suitable for the recovery of various high nickel alloys.

Nickel-iron Slag Treatment Experiment Video

Nickel-iron Slag Treatment Plant Equipment Configuration

Regarding the equipment selection of the ferronickel slag treatment program, Forui Machinery is here to explain to everyone that not all ferronickel slag is suitable for the treatment and recycling of this program. When we configure the equipment, we must decide according to the specific properties of the nickel-iron slag.

The nickel-iron slag that can use the magnetic separation process does not use the gravity beneficiation process, and the nickel-iron slag that must use the gravity beneficiation process can consider using the magnetic separation process for tailing Sweep the mine. This program is suitable for smelters, and for individual investors, you can consider simplifying the process and equipment configuration. If you have any questions about the handling of nickel-iron slag, please feel free to contact us.

You may also be interested in the following articles:

Responses