Limonite Processing Production Line, Iron Ore Dressing Plant Process

Overview

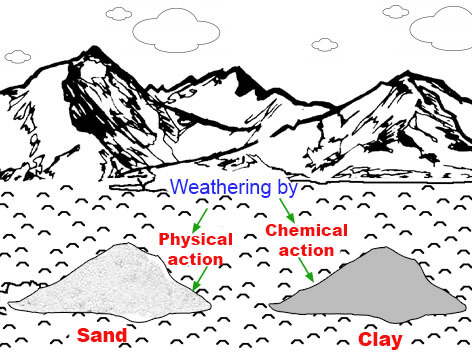

Limonite is similar to hematite and specularite and is also weakly magnetic iron ore. Its beneficiation methods include gravity beneficiation, strong magnetic separation, flotation, magnetized roasting, etc. The most commonly used are gravity beneficiation and the magnetized roasting method. Therefore, the common limonite beneficiation production line is divided into limonite gravity beneficiation production line and limonite magnetized roasting production line. Below we focus on the gravity beneficiation production line of limonite.

Limonite Gravity Beneficiation Method

Gravity beneficiation is suitable for the beneficiation and purification of coarse-grained limonite. Gravity beneficiation equipment has a small investment, low operating cost, large production line processing capacity, and high efficiency, which is suitable for most limonite concentrators.

Although the magnetized roasting method is very helpful to the improvement of the index of limonite beneficiation, it is only suitable for a small number of iron ore beneficiation plants due to the huge investment in equipment, the complicated process flow, and the high operating cost. With the same processing capacity, the investment cost of the limonite gravity beneficiation production line is only about one-tenth of that of the limonite magnetized roasting production line.

Most of the limonite is coarse-grained, and the simplest and most practical method of beneficiation is gravity beneficiation. The equipment used in the gravity beneficiation method is mainly a jig, which can beneficiate according to the specific gravity difference between limonite and waste rock, and finally obtain limonite with a larger specific gravity and waste rock with a smaller specific gravity, making limonite Separate from waste rock and play a role in improving the grade of iron ore.

However, it is impossible to complete the limonite beneficiation task by using only one jig, and auxiliary equipment such as crushers, vibrating screens, and feeders must be used to complete the limonite beneficiation task. Under normal circumstances, the limonite beneficiation production line includes a crushing process, a screening process, a gravity beneficiation process, a dehydration process, etc.

The crushing process usually uses a jaw crusher, a cone crusher, etc. The screening process adopts equipment such as circular vibrating screens and linear vibrating screens. In the gravity beneficiation process, different types of jigs are selected according to the nature of the ore. The dewatering process uses a linear dewatering screen to dehydrate the concentrate and tailings to facilitate transportation and storage.

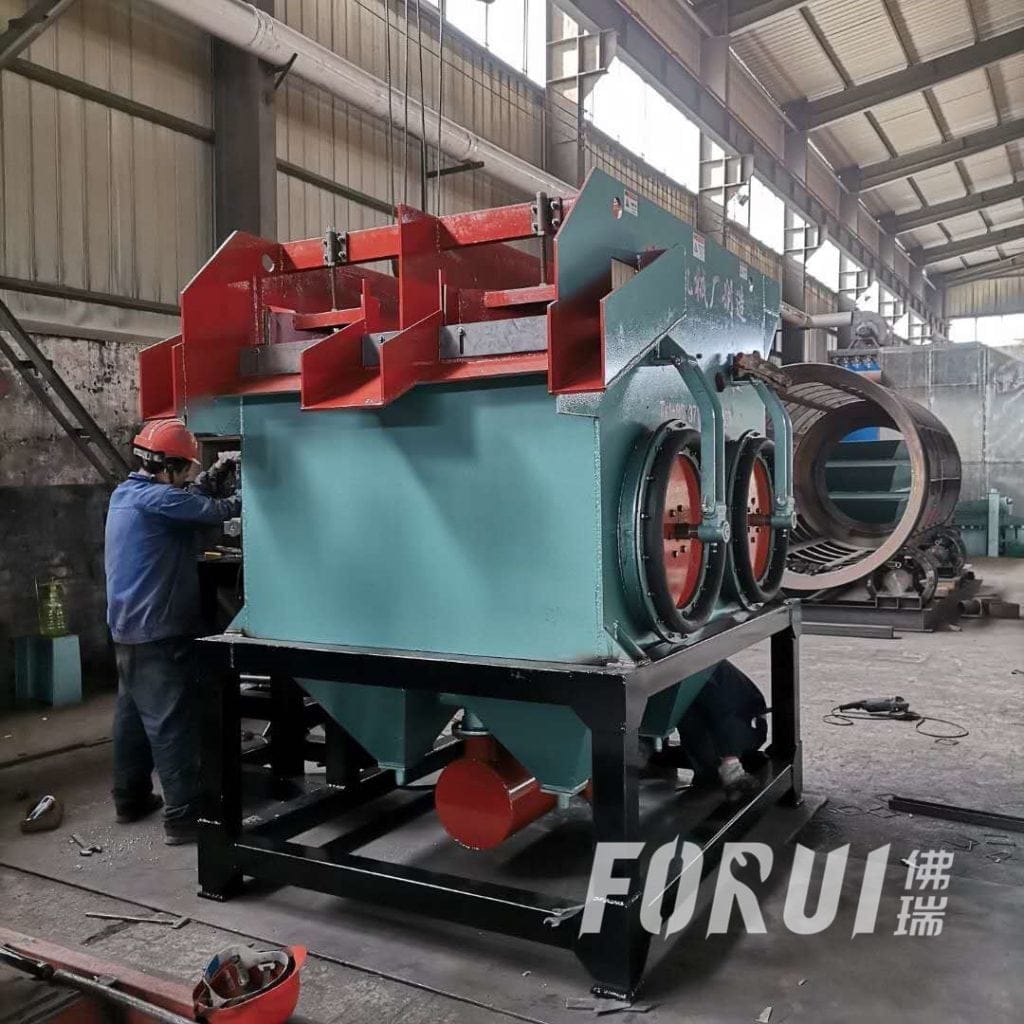

The limonite gravity beneficiation production line and the gravity beneficiation process have a significant beneficiation effect on the coarse-grained limonite beneficiation. The following is the picture of the Limonite beneficiation production line of Forui Machinery:

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us:

- Whatsapp: +8618026978087

- Email: asa.guo@foruimining.com

- Tel: +86-371-64391589

- Facebook: https://www.facebook.com/ForuiMachinery/

- Instagram: https://www.instagram.com/foruimining/

- Twitter: https://twitter.com/ForuiMachinery

- LinkedIn: https://www.linkedin.com/in/asa-guo-benefication-equipment-at-forui/